Description

THE ARG 300 3D BAND SAW IS THE FASTEST, CHEAPEST AND MOST EFFECTIVE SOLUTION DESIGNED FOR THE DIVISION OF 3D PRINTED METAL PARTS FROM THE BASE PLATE.

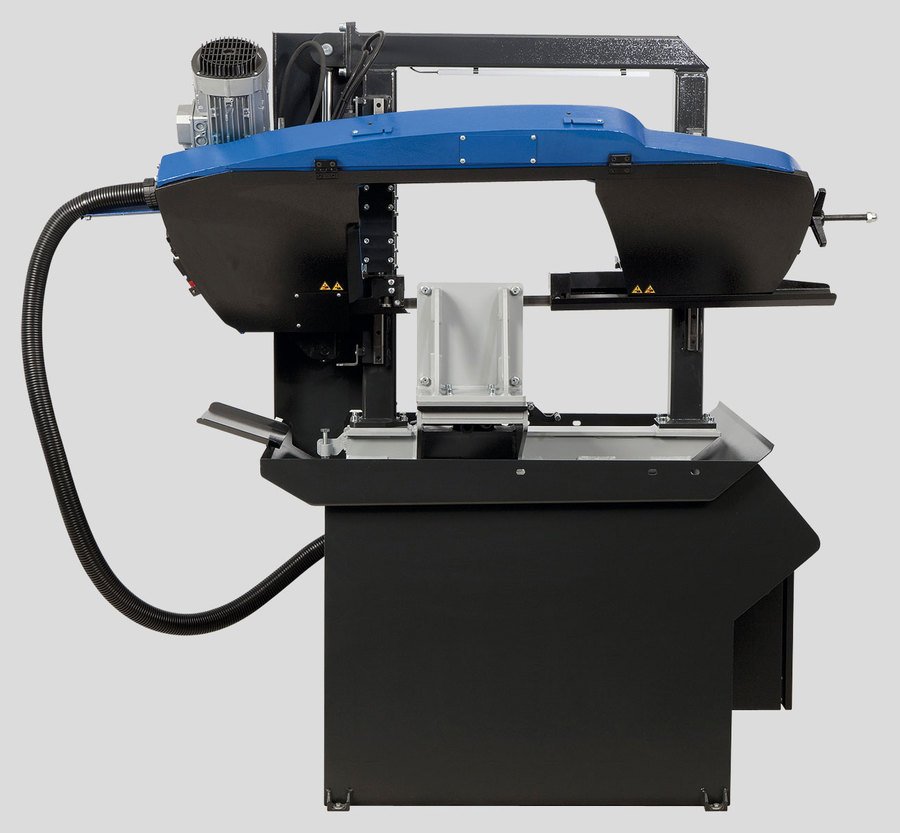

This robust two-column band saw ensures fast and precise division of the 3D-printer-product from the base plate. The cutting accuracy is 0.1 mm in all directions, the cutting width 1.5 mm. It is faster and cheaper compared to wire cut machines.

Adjustable in all directions, with a specially designed vice ensuring optimal clamping of the material. Correct clamping of the material allows setting of the cut with minimum allowances and thus saving material during printing.

A completely new and revolutionary concept of the saw arm cast is designed in a unique way. The massive cast iron arm is entirely unrivalled in the category of dual-column band saws. It ensures, in the combination with the massive dual-column arm fit moving on linear lines excellent stiffness of the whole system and an accurate cut.

The cutting tool used is an industrial Bi-metal saw blade of the size 27 x 0.9 mm. Precision of the cut is guaranteed by a three-sided hardmetal guiding before and after the cut.

Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band speed by a frequency converter in the range between 15–90 m/min., which significantly contributes to cutting accuracy and service life of the saw bands. Under the cutting area, a removable chip tub is located that collects most of the chips for the next use.

The saw blade arm moves on the linear guiding using hydraulic cylinder driven by a powerful hydraulic unit.

It features simple operation on a central control panel and infinitely adjustable feed rate into the cut. After the execution of the cut, the saw blade automatically turns off and its arm moves up to the original, adjustable position.

The machine is characterized by its overall robust design. Its base consists of a stable machine pedestal with the vice and a two-column fitting system of the arm that moves on linear guiding.

The unique saw blade arm is fitted with orbital cast-iron wheels with massive fit, driven by an industrial engine with a worm gear. All this guarantees long-term cutting precision and service life of the machine.

Technical specification

| Max. width and height of the cut | 360 x 300 mm |

| Main motor | 400 V, 50 Hz, 2,2 kW |

| Hydraulic unit motor | 400 V / 50 Hz / 0,18 kW |

| Saw blade speed | 15-19 m/min. |

| Operating vice height | 900 mm |

| Oil in the hydraulic system | cca 6 l (ISO 6743/4-HM, DIN 51 524 part 2-HLP) |

| Machine dimensions (max.) | 1900 x 950 x 1900 mm |

| Machine weight | 500 kg |