Description

Feed into the cut and back – hand-operated

Arm height adjustment – manual

Control panel – on a mobile bridge

Log handling – manual

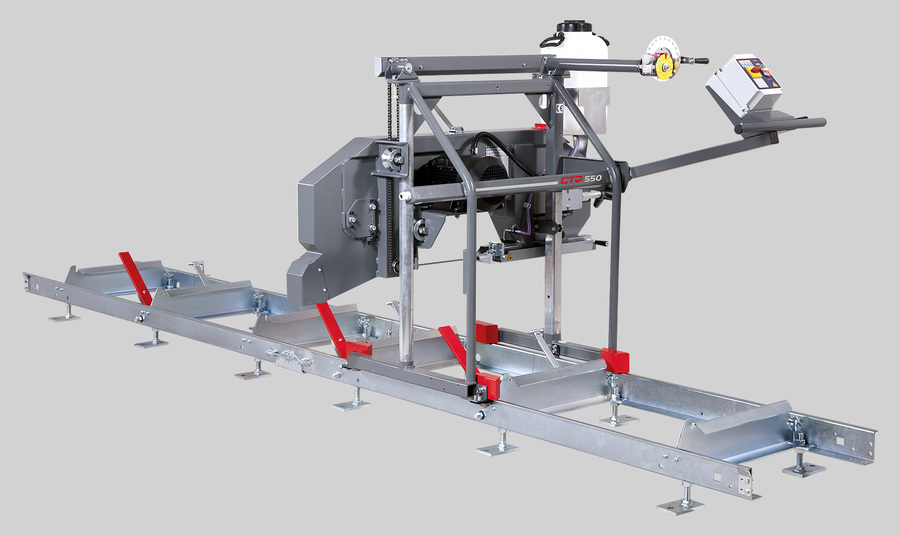

The smallest machine in the offer. It is designed primarily for cutting smaller volumes of lumber. Ideal solution for family farms, joiners’ workshops or small sawmills. Very simple hand feed into the cut and back. The control panel is placed on a mobile bridge of the saw band arm. Thanks to that the operator has closer access to the workpiece when cutting. Height is adjusted using a hand crank with adjustable scale.

First machine of its type in the world that uses bimetallic saw band which is by default used in metal band saws.

That brings the following benefits:

- very simple operation

- single saw band cuts all types of wood without tooth adjustment (sharpening, tooth setting)

- elimination of tedious, technically challenging sharpening and setting of teeth

- you can immediately start cutting wood in professional quality without any necessary experience

- bimetallic saw band easily cuts metal materials in the log such as nails, shrapnel or bullets.

- professional three-side hardmetal saw band guidance in guiding heads and robust support of all rotary parts ensure high cutting accuracy and long service life of the saw band

- maximum accuracy, like in professional machines

- no need to purchase tooth sharpener and tooth setting machine

- easy accessibility and low cost of bimetallic saw bands

Total power input of the machine of 4 kW guarantees low operating costs and easy connection to mains. You may also use a special 35 x 0.9 mm bimetallic saw band instead of the 27 x 0.9 mm bimetallic saw band. Similarly to the metal-cutting bimetallic saw band it doesn’t require any sharpening or tooth setting. You can also fit your machine with standard saw-cutting bands (35 x 0.9 mm) identical to those used in higher professional models CTR 710, 800 and 950. Larger teeth in these saw bands allow for increase of productivity when cutting large diameter logs. However, in the above mentioned saw bands it is necessary to sharpen and set the teeth regularly.

The arm is fitted with aluminium running wheels with accurate balancing against vibrations. The wheel has a groove along its circumference. The groove holds a replaceable rubber-textile belt which creates an optimum contact area between the wheel and the saw band.

The sturdily mounted running wheel is powered through a wedge belt by a professional electrical motor specially balanced against vibrations.

The tensioning wheel system moves within a solid cast iron guiding, which ensures long-term service life and setting accuracy even in long-term machine operation.

CTR series present the latest trends in construction of log saw bands with a special emphasis on maximum accuracy and long-term service life of the machine while ensuring minimum costs.

The machines are designed in an original modular execution which allows easy replacement or adjustment of all main technical sections and their individual parts. This in the long-term perspective reduces the maintenance costs and service times and therefore production stoppages as well.

Technical specification

| Max. log diameter | 550 mm |

| Max. opening tetwen blade guides | 400 mm |

| Max. elevation of blade | 465 mm |

| Min. log height | 20 mm |

| Max. depth of cut | 200 mm |

| Max. log length (standard model) | 3,6 m |

| Length track section | 2,25 m |

| Min. log length | 0,9 m |

| Saw blade motor | 4 kW |

| Sawblade | 3110 x 27÷35 x 0,9 mm |

| Weight (standard model) | 250 kg |

| Weight (track section) | 778 kg |

Nomimal current of circuit breaker is minimally 20 Ampere