Description

Feed to the cut and back – motor-powered

Arm height adjustment – motor-powered

Control panel – stationary

Log handling – hydraulic

Innovative version of the extremely succesful model CTR 800 that has been on market for 15 years now.

The key change lies in the increase of the impeller diameter from the original 500 mm to 600 mm. This allows you now to use 1.3 mm thick saw blades in contrast to the formerly used 0.9 – 1,1 mm blades. Using a 1.3 mm thick saw blade is the newest trend in band saws with narrow blades. The risk of blade rippling in the cut even at high speeds is substantially reduced. Thus, the machine productivity and the cutting accuracy are considerably increased.

Apart from the new machine design, there are many technological adjustments that improve user comfort as well as the quality and durability of the machine.

The design of the arm (now 40 kg heavier) and the sliding hard chromium rods has been reinforced. Due to heavier weight, the motor is now equipped with a brake, as in machines of the highest category. It significantly increases the accuracy of stopping at the desired point and contributes to the service life of the whole uplift system.

The sliding speed backwards in CTR 800 H has been increased as well, which means you can now use as hydraulic accessories the log taper adjuster with a rotary and a powered cylinder. To increase the machine productivity, you can now also install the feeder of the cut material together with the chute, or the belt conveyor XRB 800 which has been for space saving purposes partially integrated into the basic machine frame. The belt conveyor enables connecting of the machine to a complete line for the processing of XR logs.

Universal log band saw with hydraulic accessories. With maximum cutting diameter of 83 cm the saw is suitable for most lumber. Its construction is based on the popular model CTR 800 S, which is established on an

elevated sliding frame with complete hydraulic accessories. The hydraulic accessories easily handle the workpiece, significantly increases the productivity of the machine and saves labour costs.

The basic version is fitted with following hydraulic accessories:

- Log Clamping – 2x

- Retractable Angle – 3x

- Retractable Log Turner – 1x

Thanks to the unique modular design of CTR series the machine is fitted with many fitting points for hydraulic equipment. That allows large variability of its placement with regard to the total cutting length and specifics of the processed material. A wide, massive running bridge of the band saw arm and robust running sections with double-sided steel guidance ensure undisturbed operation when cutting and even at high running speeds.

Professional execution of all main technical units, such as running wheels with their bearing system, saw band arm construction, powering and feeding system, etc. ensure maximum service life and machine accuracy even under the most difficult operating conditions. Continuously adjustable machine feed to the cut and back and band saw arm height adjustment. Travel speed is displayed on the digital display. The central control panel is stationary and it’s placed on the main running section.

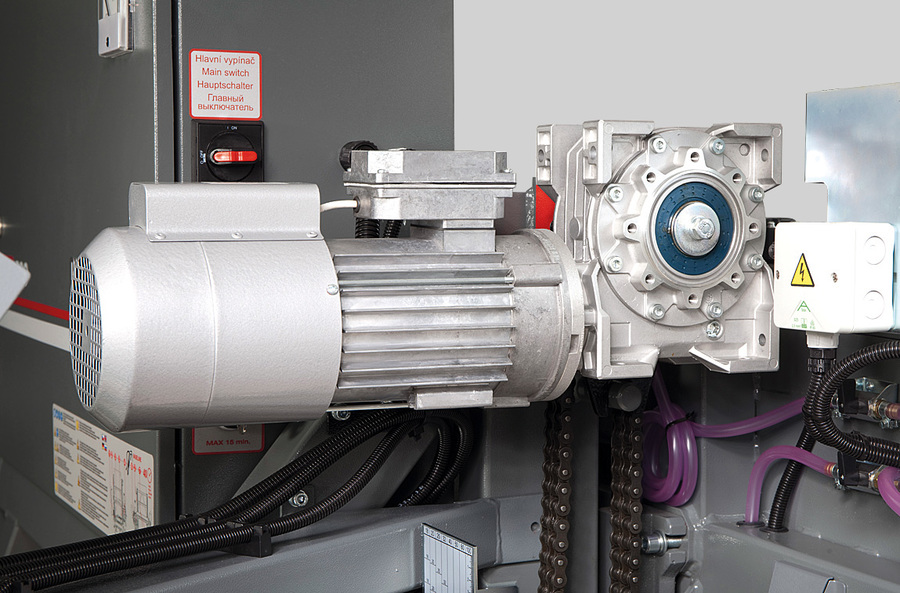

This allows convenient machine control from a single place with complete hydraulic accessories. The feed to the cut and back is driven by an electric motor with worm gearbox controlled by a frequency converter. You can change the speed of travel simply by turning the potentiometer on the control panel. The end stops provide automatic deceleration and stopping in end positions.

The massive band saw arm is borne on adjustable hard-chromium rods (for moving up and down) which ensure absolute accuracy of band saw arm movement and virtually unlimited service life, if the machine is lubricated regularly. The vertical movement of the arm is provided by double-sided synchronous chain transmission powered by an electric motor with worm gearbox. The movement controlled from the central panel has two modes of speed – rapid feed and slow feed for accurate movement to a desired position. This system can be always additionally equipped with electronic metering which automatically moves to the specified position.

The arm is fitted with blade wheels made of high-quality grey cast iron with accurate balancing against vibrations. The wheel has a groove along its circumference. The groove holds a replaceable rubber-textile belt which creates an optimum contact area between the wheel and the saw blade.

The sturdily mounted blade wheel is powered through a wedge belt by a professional electrical motor specially balanced against vibrations. The tensioning wheel system moves along a sturdy cast iron wedge guide with adjustable pressure bar, which allows highly accurate adjustment without any free travel even in long-term machine operation.

The saw blade is guided in the cut by hardened and ground guide pulleys. This system can be fully adjusted in all directions and it ensures optimum position of guide pulleys and the saw band.

On the moving bar additionally in combination with the hardmetal blade guiding.

In order to ensure accuracy of the cut the guide pulley on the operator’s side moves as close as possible to the workpiece. Simply operated massive bearing system. It can be motor-powered and controlled as an auxiliary device from the control panel.

Gravity cooling and lubricating of the band with adjustable outlets in both guide pulleys ensure that the saw band is in optimum condition during cutting.

Stable running sections with steel arm bridge guides form the basis of the machine. They are sufficiently dimensioned for maximum diameters of logs as well. They were designed reflecting the practice, therefore designed to cope with very hard operating conditions. Cut length is virtually unlimited in all types of machines, it only depends on the length of running gear installed.

CTR series present the latest trends in construction of log saw bands with a special emphasis on maximum accuracy and long-term service life of the machine while ensuring minimum costs.

The machines are designed in an original modular execution which allows easy replacement or adjustment of all main technical sections and their individual parts. This in the long-term perspective reduces the maintenance costs and service times and therefore production stoppages as well.

Accessories – there is a wide range of accessories to all of these machines; they simplify and accelerate machine operation and influence its production. Our original modular system allows additional installation of necessary equipment at any time, because all basic versions of machines include all fitting spots including holes and threads.

Technical specification

| Max. log diameter | 830 mm |

| Max. opening betwen blade guides | 750 mm |

| Min. blade height from support beam | 685 mm |

| Min. log height | 30 mm |

| Max. depth of cut | 450 mm |

| Max. log length (standard model) | 4,5 m |

| Length track section | 3 m |

| Min. log length | 1,2 m |

| Saw blade motor | 7,5 (11) kW |

| Horizontal feed motor | 1,5 kW |

| Vertical feed motor | 0,55 kW |

| Hydraulic motor | 5,5 kW |

| Hydraulic oil | ISO 6743/4-HM, DIN 51 524 part 2-HLP |

| Sawblade | 4920 x 35 ÷ 40 x 0,9 ÷ 1,1 mm |

| Weight (standard model) | 1500 kg |

| Weight (track section) | 250 kg |